Introduction to Custom Aluminum Extrusion: A Game Changer in Manufacturing

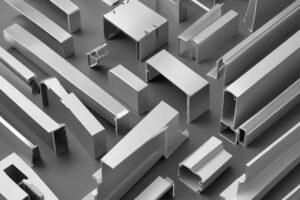

In the ever-evolving landscape of manufacturing, custom aluminum extrusion stands out as a game changer, unlocking possibilities that many industries have only begun to explore. With Silver City Aluminum at the forefront, businesses can tap into a world where flexibility, optimization of material usage, and enhanced product performance come together seamlessly. As industries look for ways to innovate and streamline their operations, custom aluminum extrusion emerges as a solution that not only meets but often exceeds expectations.

The advantages of custom aluminum extrusion lie in its ability to provide unique solutions tailored to specific project requirements. Companies across various sectors—be it marine, automotive, construction, or lighting—are turning to custom extrusion to enhance product integrity, reduce manufacturing costs, and achieve design goals that were previously unattainable. This shift toward innovative solutions reflects a broader trend in manufacturing that prioritizes efficiency, sustainability, and advanced engineering practices.

As we dive deeper into the realm of custom aluminum extrusion, it’s essential to recognize the underlying principles that make it a preferred choice for many companies. These principles include the ability to design bespoke profiles for innovative applications, explore substantial design benefits, and integrate aspects of precision engineering into the finished product. This article aims to illuminate how custom aluminum extrusion can redefine your projects and elevate performance to new heights.

Understanding the Design Benefits of Custom Aluminum Extrusions

Understanding the benefits of customized designs begins with flexibility. Custom aluminum extrusions allow for an infinite range of shapes and sizes that traditional manufacturing methods often cannot achieve. This versatility empowers engineers and designers to tailor components precisely to their specifications, adapting to the unique requirements of each application. Innovations in extrusion technology enable the creation of complex and intricate profiles that align with modern design principles, paving the way for unprecedented functional and aesthetic outcomes.

Flexibility in design is not merely about creating unique shapes; it also encompasses the ability to adjust designs in response to market demands. As customer needs evolve and new trends arise, the ability to pivot quickly without substantial retooling or overhauls is crucial for maintaining competitive advantage. Silver City Aluminum’s capabilities in custom aluminum extrusion support an agile manufacturing environment, which is paramount as the industry shifts towards just-in-time production methods.

Moreover, the adaptable nature of custom designs encourages collaboration between engineers and designers. Rather than being constrained by predetermined shapes, teams can iterate on designs, optimizing for performance, durability, and aesthetic appeal. This collaborative spirit fosters innovative solutions, allowing businesses to launch new products that stand out in a crowded market while minimizing time-to-market significantly.

Optimizing Material Usage in Custom Extrusions

Optimizing material usage is another key advantage of custom extrusions. By designing components that are both lightweight and strong, companies can reduce waste and energy consumption, leading to more sustainable practices. Silver City Aluminum commits to using 99.9% recyclable materials, ensuring that projects yield not just high-functioning components but also mitigate environmental impact. This eco-conscious approach aligns with the growing consumer demand for sustainability, making it a strategic choice for businesses looking to enhance their brand image in a competitive market.

The importance of material efficiency cannot be overstated in an era where resource conservation is critical. Custom aluminum extrusions can be engineered to minimize excess while maximizing structural integrity. For manufacturers, this translates into lower costs associated with raw materials and processing, ultimately affecting the bottom line positively. By integrating efficient design methods with aspects of precision engineering, firms can achieve strong and lightweight components without sacrificing performance.

Furthermore, opting for custom extrusions allows for the consolidation of parts in manufacturing processes. By designing complex profiles that combine multiple functionalities into a single component, companies can streamline assembly processes, reduce the overall number of parts, and enhance operational efficiency. This not only conserves materials but also simplifies logistics and inventory management, paving the way for a more efficient production cycle.

Enhanced Product Performance through Precision Engineering

Enhanced product performance is arguably the most significant benefit of adopting a custom aluminum extrusion design. This approach allows manufacturers to create products that not only meet stringent performance standards but also exceed them. For instance, when producing heat sinks for LED lighting systems, Silver City Aluminum utilizes its expertise to craft extrusions designed for optimal heat dissipation. These innovations translate into longer-lasting and more efficient products, directly resulting in cost savings and increased customer satisfaction.

Precision engineering plays a pivotal role in achieving the desired performance outcomes in custom aluminum extrusion. Each extrusion is subjected to rigorous quality control measures, ensuring that specifications are met at every stage of the process. From the initial design phase through to fabrication and finishing, meticulous attention to detail guarantees that the final product is crafted to perfection, minimizing defects and maximizing performance.

Moreover, the ability to design with performance in mind facilitates the creation of specialized applications that address specific industry needs. Whether it is developing components for aerospace applications or robust frames for marine environments, precision engineering coupled with custom aluminum extrusion offers unparalleled opportunities for improving functionality. In doing so, companies are not only able to meet existing market demands but also pioneer new applications that challenge the limits of traditional manufacturing.

Real-World Success Stories: The Impact of Custom Solutions

Real-world success stories from Silver City Aluminum clients illustrate these benefits in action. A marine manufacturer needed a solution for a new boat design that required lightweight yet durable railings. By collaborating on a custom extrusion that combined structural integrity with aesthetic appeal, Silver City Aluminum provided a product that met the company’s high standards for performance while staying within their budget and timeline. Feedback confirmed that these customized extrusions significantly enhanced the overall design and functionality of the boats, making them not just safer, but also more visually appealing without incurring unnecessary weight penalties.

Additionally, an automotive company faced challenges with weight efficiencies and turned to Silver City Aluminum for a custom approach. Through inventive aluminum extrusion design, they reduced the weight of specific components without compromising strength. This improvement not only enhanced fuel efficiency but also allowed for greater design flexibility, resulting in a stronger, more dynamic vehicle platform. The innovative solutions presented by Silver City Aluminum proved crucial in aiding their client to pivot toward more sustainable practices while fostering competitive advantages.

Such testimonials reinforce the remarkable adaptability and performance enhancement that custom aluminum extrusions deliver across diverse industries. Silver City Aluminum’s commitment to exceptional service and innovative solutions solidifies its status as a lead partner for businesses seeking high-quality, tailored aluminum solutions. The ability to seamlessly integrate client feedback and engineering insights into the design process further emphasizes the collaborative nature of successful partnerships in the realm of custom aluminum extrusion.

The Path to Sustainable Practices with Custom Aluminum Extrusions

As we consider the landscape of custom aluminum extrusion, it’s clear that the ability to forge unique designs enhances not just project outcomes but also drives industries toward sustainable practices. For companies looking to boost their operational efficiency while championing eco-friendly initiatives, custom aluminum extrusion is the way forward. The emphasis on utilizing 99.9% recyclable aluminum aligns with both consumer expectations and regulatory demands surrounding environmental responsibility.

In today’s fast-paced market, organizations that prioritize sustainability often enjoy enhanced brand loyalty and customer trust. By integrating environmentally friendly practices into their manufacturing processes, companies can effectively communicate their commitment to responsible production. Custom aluminum extrusion not only supports these efforts but also offers the performance advantages needed to remain competitive in increasingly eco-conscious industries.

Moreover, the shift to sustainable practices through custom solutions will likely influence future manufacturing standards. As environmental regulations tighten and consumers become more discerning about the products they purchase, businesses must adapt to stay relevant. Custom aluminum extrusion is a forward-thinking approach that champions innovation, flexibility, and a commitment to sustainability while delivering products that meet rigorous quality and performance standards.

Conclusion: Your Project’s New Partner in Innovation

In conclusion, embracing the benefits of custom aluminum extrusion with a partner like Silver City Aluminum offers a strategic advantage in today’s manufacturing climate. By opting for tailored solutions, businesses can experience increased flexibility, optimized material usage, and elevated product performance—all while supporting sustainable practices. The potential for innovative solutions within this manufacturing niche is vast, making it a fertile ground for creativity and advancement.

The collaboration that Silver City Aluminum fosters with its clients exemplifies the power of partnership, blending skillful engineering with committed service to produce outstanding results. Companies looking to transform their projects should consider the unique capabilities offered by custom aluminum extrusion as a vital resource in their planning and execution phases.

Ready to unlock the possibilities for your next project? Reach out to Silver City Aluminum today and see how they can elevate your designs to new heights.

Looking for expert guidance or custom aluminum solutions for your next project? Our team at Silver City Aluminum is ready to assist with your extrusion, fabrication, and finishing needs. Whether you’re working on a new design or need advice on complex requirements, feel free to call us at 508-824-8631 or email us at engineering@scaluminum.com. Let’s make your vision a reality with precision and quality!