The Art and Science of Custom Aluminum Profiles

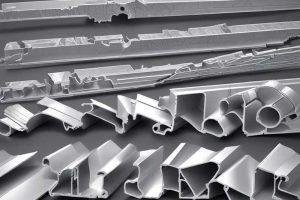

In the dynamic world of aluminum extrusions, the design of custom aluminum profiles represents a synthesis of artistic vision and scientific precision. To succeed in crafting these profiles, it is necessary to grasp not only the material properties of aluminum but also the manufacturing capabilities at one’s disposal. This intricate interplay of skill and knowledge defines the work done at Silver City Aluminum, a company that has established itself as a leading provider in this space. With over three decades of experience and a commitment to excellence, they adeptly navigate the complexities that come with creating custom aluminum solutions for diverse industries.

The journey toward developing successful custom aluminum profiles begins with effective collaboration between designers and manufacturers. Unlike run-of-the-mill products, custom aluminum profiles require in-depth conversations about their intended application, structural requirements, and aesthetic aspirations. Silver City Aluminum fosters an atmosphere of open dialogue that engenders shared understanding, thus ensuring that every detail is honed to perfection. Whether crafting sleek automotive components or robust marine fixtures, the initial stages focusing on communication and alignment can make all the difference in the final product’s performance and visual appeal.

Moreover, engineers tasked with designing custom aluminum profiles must comprehend the intricacies of the extrusion process. This involves a firm grasp of different aluminum alloys, dimensional constraints, and geometric complexities. Each factor carries weight during design and affects production feasibility. By collaborating closely with Silver City Aluminum, designers can leverage the latter’s extensive expertise to refine their designs in a way that maximizes functionality while minimizing potential obstacles in production. Thus, understanding the limitations of extrusion technology is vital, allowing teams to design aluminum profiles that are not just innovative, but also manufacturable within set timelines and budgetary constraints.

Understanding Extrusion Design Tips

Designing custom aluminum profiles requires careful attention to a multitude of extrusion design tips. A primary consideration is the shape and complexity of the profile, as these elements can significantly affect the efficiency of the extrusion process. For example, excessively intricate designs may compromise the uniformity of the extrusion and lead to production delays or issues with structural integrity. Emphasizing simplicity where possible can result in more straightforward manufacturing and improved performance in custom aluminum profiles.

Another key design tip revolves around optimizing wall thickness. Designers should aim for a balance that maintains strength while minimizing weight and material usage. Thick walls can add unnecessary weight, while overly thin sections may lead to rigidity issues. By consulting with engineers from Silver City Aluminum, those in charge of the design process can gain insights into what thicknesses are advisable based on the intended application and anticipated stressors. For instance, while designing frames for construction, thicker walls may be necessary for load-bearing structures while lighter designs may be acceptable for decorative elements.

Furthermore, another aspect of extrusion design is considering thermal and mechanical performance. Different aluminum alloys offer varied properties in relation to strength, corrosion resistance, and thermal conductivity. A well-thought-out design process should involve assessing the working environment and performance demands to ensure the selected alloy will meet the end-use specifications. Silver City Aluminum experts can provide guidance on selecting the right alloy to ensure durability without compromising other performance characteristics, thus yielding a final product that meets the operational challenges head-on.

Optimizing Custom Aluminum Solutions for Industry-Specific Needs

Engineers and designers must tailor their custom aluminum solutions to meet the specific requirements of various industries. Sectors like marine, automotive, lighting, and construction each have distinctive challenges and standards that must be adhered to during the design process. For instance, marine applications often demand components that are corrosion-resistant and durable enough to withstand harsh environmental conditions. Collaborating with Silver City Aluminum allows for the integration of these critical attributes into the design phase, ensuring that the final product can deliver in real-world conditions.

In the automotive sector, the focus might shift toward reducing weight to enhance fuel efficiency, while still maintaining the necessary structural support. This often calls for intricate designs that leverage advanced aluminum alloys to create strong, lightweight profiles. Silver City Aluminum’s capacity for rapid prototyping provides an effective way for automotive engineers to test and iterate on designs quickly, allowing for real-world testing before mass production. The result is a streamlined design process that leads to high-performance products that meet industry mandates.

Lighting solutions represent another area where custom aluminum solutions shine. Designers must consider not just the aesthetic appeal but also the functional aspects, including heat dissipation. Aluminum is a popular choice in lighting design because of its lightweight and thermal conductivity properties. Silver City Aluminum’s expertise in developing heat sink profiles ensures the finished product runs efficiently, lengthening the lifespan of the lighting system. Understanding how to optimize these profiles based on specific lighting applications will lead to solutions that are both beautiful and functional, making them attractive to manufacturers and end-users alike.

The Role of Prototyping and Testing in Design

One of the cornerstones of creating effective custom aluminum profiles is the prototyping and testing phase. Engaging manufacturers like Silver City Aluminum during this process is essential, allowing designs to transition from theory to practice. By creating prototypes early in the design phase, engineers can identify potential flaws or design oversights that may not be apparent during the early conceptual stages. This iterative process is invaluable for refining designs and ensuring they meet both functionality and aesthetic standards.

Furthermore, testing prototypes under real-world conditions can provide critical insights into the performance of the custom aluminum profiles. Whether examining structural integrity, thermal performance, or aesthetic appeal, these evaluations are crucial before full-scale production begins. By incorporating feedback from testing, designers can make informed adjustments that enhance the overall product quality. Silver City Aluminum’s capabilities in precision CNC machining and rapid prototyping expedite this phase, allowing teams to refine their designs promptly and effectively.

Moreover, robust testing protocols not only improve the final product but also inform future designs by uncovering design trends or demands arising from user experiences. Engaging both manufacturers and clients in this phase fosters dialogue about performance expectations, functionality, and aesthetic considerations. This collaboration further solidifies the relationship between the design team and the manufacturer, culminating in a shared goal of delivering high-quality, custom aluminum solutions that exceed user expectations.

Aesthetic Considerations in Custom Aluminum Profiles

When it comes to custom aluminum profiles, aesthetics play a vital role, particularly in industries where visual appeal is paramount. Designers must work diligently to create profiles that not only function effectively but also align with a client’s branding and design philosophy. The ability to customize finish options, including anodizing and powder coating, can significantly enhance the visual impact of aluminum products. Silver City Aluminum excels in this area, offering a wide range of finishing techniques that contribute to the overall appeal and durability of the final product.

A unique color finish can transform an otherwise standard aluminum profile, making it visually engaging while ensuring it harmonizes with its surroundings. For architectural projects, the integration of custom anodizing options provides an opportunity to add depth and texture, elevating the visual narrative of the building’s exterior or interior. This commitment to aesthetics must be closely matched with functionality; therefore, engaging in early discussions with manufacturers during the design phase ensures that both visual and performance standards are cleared without compromise.

The smoothness of surfaces can also be a critical aspect of a profile’s success in certain applications. Industries such as lighting and automotive often require aesthetic considerations where luminescence or sleekness can improve user experience. Silver City Aluminum’s advanced finishing processes ensure that high levels of surface quality are achieved without sacrificing durability. By addressing aesthetic concerns effectively early in the design process, engineers can contribute to a polished final product that resonates with end-users and stakeholders alike.

Commitment to Sustainability in Aluminum Design

In an age where environmental responsibility is increasingly prioritized, sustainability has become a pivotal factor in aluminum design considerations. Manufacturers like Silver City Aluminum lead the charge by utilizing 99.9% recyclable aluminum, aligning production capabilities with eco-conscious practices. Designers should view this commitment not merely as a compliance element but as an integral part of their branding strategy, enhancing market appeal among clients who value sustainability.

Additionally, the choice of aluminum as a material itself is influenced by its recyclability and energy efficiency. Modifying designs to incorporate recyclable materials can also lower the carbon footprint of the final products, making the entire design and production cycle greener. Silver City Aluminum’s focus on minimizing waste during the production process dovetails with these goals, maximizing efficiency while contributing to a sustainable future.

Furthermore, collaboration with manufacturers who prioritize sustainable practices opens the door to innovative design solutions. By engaging in conversations about the lifecycle of products from design to disposal, engineers can craft profiles that not only meet performance criteria but also adhere to green manufacturing initiatives. This holistic approach can lead to new avenues of growth and innovation that not only fulfill market demands but also position both manufacturers and designers as leaders in sustainable practices.

Building Effective Relationships with Manufacturers

Equally important as the design process is fostering strong, continuous relationships with manufacturers like Silver City Aluminum. Open communication lines throughout the project lifecycle lead to better alignment, clarity, and understanding, ultimately resulting in a higher quality custom aluminum end product. Engaging in ongoing dialogue can address potential concerns promptly, facilitating a smooth workflow in bringing custom profiles to fruition.

Regular check-ins and design reviews create opportunities to assess project statuses and resolve any emerging challenges collaboratively. Such transparency fosters a culture of trust between teams and manufacturers, enhancing the efficiency of operations from ideation through to final delivery. By valuing this interaction, parties involved can ensure that expectations are met and potentially improved upon, echoing the spirit of collaboration that defines successful projects.

Additionally, a strong partnership extends beyond the design phase to encompass post-production assessments and long-term support. By keeping communication channels open, companies can gather valuable feedback for future projects, evolving their understanding of customer needs and market trends. Silver City Aluminum’s commitment doesn’t end at delivery; they remain invested in nurturing these relationships, showcasing their dedication to providing tailored aluminum solutions that resonate in various industries.

Conclusion: A Path Toward Custom Aluminum Excellence

As we sum up the journey of creating custom aluminum profiles, it is clear that success is found in the details, collaboration, and attention to industry-specific criteria. By ensuring thorough communication, understanding the nuances of material design, and embracing sustainable practices, engineers and designers can craft innovative solutions that truly stand out. Partnering with an expert manufacturer like Silver City Aluminum significantly enhances this process, supplying not just technical capabilities but also strategic insight that brings unique aluminum extrusion profiles to life.

The commitment to custom aluminum solutions from Silver City Aluminum empowers industries to meet their demands expediently. With a focus on maintaining high quality, rapid turnaround times, and environmentally-friendly practices, the company remains a steadfast ally to engineers and designers alike. Ultimately, the ability to fuse artistry and precision in engineering aluminum designs positions custom aluminum profiles as multifaceted solutions adaptable to various applications.

For high-quality custom aluminum extrusions, fabrication, and finishing services, Silver City Aluminum is ready to assist with all your project needs.

Looking for expert guidance or custom aluminum solutions for your next project? Our team at Silver City Aluminum is ready to assist with your extrusion, fabrication, and finishing needs. Whether you’re working on a new design or need advice on complex requirements, feel free to call us at 508-824-8631 or email us at engineering@scaluminum.com. Let’s make your vision a reality with precision and quality!