Understanding Aluminum Alloys in Extrusion Processes

In the expansive world of manufacturing, particularly in the extrusion of aluminum products, the selection of aluminum alloys plays a pivotal role. These alloys are not merely inert materials; they are specific chemical mixtures designed to impart distinct properties that enhance the performance and durability of the final product. A broad spectrum of aluminum alloys exists, each tailored to meet a range of application requirements, thereby influencing everything from strength and weight to corrosion resistance and workability.

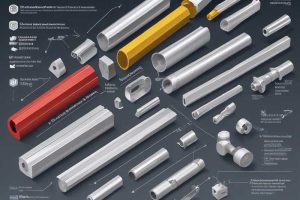

Aluminum alloys can be classified into two primary categories: wrought and cast. Wrought alloys are further subcategorized into series based on their principal alloying elements, such as copper, magnesium, and silicon. For example, the 6000 series aluminum alloys are particularly popular due to their excellent corrosion resistance and good machinability, making them ideal for applications in construction and automotive industries. Conversely, the 7000 series alloys are enriched with zinc, providing exceptional strength, which is crucial for applications in aerospace and sports equipment.

Understanding these classifications is vital for successful material selection during the aluminum extrusion process. With each series possessing unique mechanical properties and heat treatment responses, a thorough assessment of intended use cases is necessary. Silver City Aluminum leverages this knowledge to help clients select the most appropriate alloys, ensuring not just compliance with safety and performance standards but also enhancing the overall efficiency of manufacturing processes.

Exploring the Extrusion Process

The extrusion process is a fascinating and intricate method used to manufacture shapes from aluminum alloys. At its core, this process involves forcing aluminum billets through a die to create continuous lengths of material in specific cross-sectional shapes. The significance of proper execution in the extrusion process cannot be overstated; it is crucial for ensuring the quality and integrity of the final product. Silver City Aluminum employs advanced technology and techniques to optimize this process, ensuring high-quality outcomes consistently.

During the aluminum extrusion process, the aluminum is first preheated to a precise temperature that makes it easier to work with. Subsequently, the heated aluminum is pushed through a die that defines its shape. The entire operation demands strict control over variables such as temperature, pressure, and speed, guaranteeing that the resulting extrusion meets the desired specifications with high repeatability. Silver City Aluminum’s state-of-the-art facilities enable real-time monitoring and adjustments throughout this process, encompassing every phase from the initial heating to the final cooling stage.

The extrusion process does not just produce raw aluminum shapes; it also directly influences material properties. For instance, the deformation of aluminum during extrusion enhances its strength due to strain hardening. This fact underscores the need for skilled operators and precise process control. With a keen focus on manufacturing efficiency, Silver City Aluminum can yield a higher output while reducing waste, ultimately offering clients better value through enhanced productivity and lower costs.

Material Selection: Key to Project Success

Material selection stands at the crossroads of quality and cost-effectiveness, particularly when it comes to aluminum extrusion. Choosing the right alloy is essential not just for meeting the functional demands of a project but also for achieving sustainability targets. The significance of material selection is amplified by the fact that the performance of the final product hinges on the inherent properties of the chosen alloy, which influences everything from longevity to maintenance needs.

In industries encompassing marine, automotive, lighting, and construction, the specific demands can vary widely. For instance, a marine application may require a material that excels in corrosion resistance due to constant exposure to moisture and saltwater. Silver City Aluminum’s experience in various industries means they understand these nuances, offering clients tailored recommendations based on comprehensive knowledge of different aluminum alloys and their behaviors.

Moreover, the consultation process does not end with just recommending an alloy. Silver City Aluminum takes into account the operational environment, projected loads, and expected wear when assisting clients in their material selection journey. This thorough approach ensures that businesses are not only receiving products that function well but also materials that extend the lifecycle of their projects, reducing the frequency of replacements and repairs, thus fostering sustainability.

The Importance of Performance Attributes

The performance attributes of aluminum alloys are critical factors to consider when embarking on extrusion projects. Essential properties such as thermal conductivity, strength, weldability, and formability can vary greatly from one aluminum alloy to another. These characteristics not only determine whether a product can withstand specific environmental conditions but also influence how easily it can be manipulated during the manufacturing process.

Thermal conductivity, for example, is a key consideration for applications involving heat transfer, such as in electronics and automotive radiators. Aluminum alloys with high thermal conductivity can efficiently dissipate heat, prolonging the life of the components involved. Strength and weldability, on the other hand, are especially significant for structural applications, where the ability to withstand loads without failure is crucial. The intuition and expertise of Silver City Aluminum facilitate a precise matching of these attributes to client needs, thereby fostering not just effective, but also innovative product designs.

Moreover, as industries evolve and require more efficient materials and processes, performance attributes of materials become even more relevant. The ability to meet stringent safety standards, alongside enhancing energy efficiency, has never been more critical. Silver City Aluminum’s ongoing dedication to understanding the constantly shifting landscape of material performance allows them to maintain a competitive edge in the aluminum extrusion market, ensuring clients receive solutions that not only meet but exceed current industry standards.

Sustainability in Aluminum Manufacturing

In recent years, sustainability has transitioned from a buzzword to a central pillar of modern manufacturing practices. For companies like Silver City Aluminum, embracing sustainable practices offers not only a competitive advantage but also a responsible approach that resonates with environmentally-conscious clients. The use of 99.9% recyclable aluminum in their extrusion processes underscores their commitment to reducing environmental impact while delivering high-quality products.

Aluminum itself is a highly valuable recyclable material; it can be reused indefinitely without degrading its properties. This inherent recyclability reduces energy consumption and greenhouse gas emissions, supporting global sustainability efforts. By prioritizing recyclable sources, Silver City Aluminum aligns their operational practices with the broader goals of environmental stewardship. Their processes are designed to minimize waste and energy consumption, emphasizing the creation of value through sustainability.

This commitment to eco-friendly manufacturing not only serves the company’s mission but also meets a growing demand from industries for sustainable materials. Clients increasingly seek partners who share their values on environmental responsibility. Therefore, choosing Silver City Aluminum sends a message of commitment to sustainability, positively impacting brand reputation and positioning businesses as responsible corporate citizens.

Client-centric Approach to Service Delivery

The heart of Silver City Aluminum’s success lies in its client-centric philosophy. Rather than offering one-size-fits-all solutions, the company prides itself on understanding the unique needs and challenges of each client. This approach is reflected in their extensive range of services, which encompass custom aluminum extrusion, rapid prototyping, fabrication, finishing, and packaging. Each project receives personalized attention to ensure that all aspects are tailored to meet individual specifications.

Moreover, the company’s streamlined processes assure clients get exceptional lead times without compromising quality. With a standard turnaround of just three to four weeks—well ahead of the industry norm—Silver City Aluminum addresses urgent demands with agility, accommodating special orders within days. This responsiveness demonstrates their commitment to customer satisfaction, fostering long-term relationships based on trust and reliability.

In addition to technical expertise, Silver City Aluminum emphasizes communication throughout the project lifecycle. This transparent dialogue not only ensures alignment on expectations but also allows for any potential adjustments to be made proactively. Clients appreciate this collaborative approach—accessing expert guidance while feeling confident that their specific needs and deadlines will be met.

Comprehensive Range of Services

The capabilities of Silver City Aluminum extend well beyond mere aluminum extrusion. Their comprehensive range of services includes fabrication and finishing, enabling the company to be a one-stop shop for all aluminum product needs. Not only does this consolidation improve efficiency for clients, but it also enhances the quality of the final product, as all stages of production are overseen and executed by a single, experienced team.

Custom aluminum extrusion is the company’s core competency, but their in-house capabilities include CNC machining, mitering, punching, drilling, and assembly. This breadth of services means that the company can accommodate small scale manufacturing as well as large complex orders without compromising on speed or accuracy. Whether designing intricate components for a marine vessel or producing sturdy frames for automobiles, Silver City Aluminum’s adaptive fabrication solutions cater to diverse client requirements.

In addition, the finishing services offered by Silver City Aluminum—including powder coating and anodizing—further enhance the aesthetic and functional qualities of aluminum products. The company’s state-of-the-art finishing techniques not only improve appearance but also increase durability, ensuring products remain resilient against environmental factors. This holistic approach guarantees that all client projects are manoeuvred through processes designed to meet strict quality assurance and speed requirements.

Why Silver City Aluminum Stands Out

When it comes to the myriad of options available for aluminum extrusion, Silver City Aluminum distinguishes itself on several fronts. Their expertise and precision in engineering custom aluminum solutions are remarkable. Backed by over three decades of industry experience, they understand the nuances of aluminum alloys and extrusion processes, ensuring they meet varied needs with rigor and excellence.

Their commitment to fast lead times is another significant differentiator. While the industry often operates on extended timelines, Silver City Aluminum has established itself for its ability to deliver projects swiftly without sacrificing quality, making them an attractive partner for clients facing time-sensitive demands.

Furthermore, Silver City Aluminum champions environmentally friendly practices, using 99.9% recyclable materials in a manner that prioritizes sustainability while maintaining production efficiency. This alignment with eco-conscious goals resonates well with an evolving market that increasingly values sustainable manufacturing. Overall, Silver City Aluminum is not just a supplier but a trusted partner committed to delivering quality with integrity.

Conclusion: Partnering for a Sustainable Future

In conclusion, the nuances of selecting the appropriate aluminum alloy for extrusion are significant, extending beyond functionality to also embrace sustainability and quality. Silver City Aluminum is a beacon of this philosophy, enriching the industry through superior quality products and responsible practices. As businesses in various sectors—marine, automotive, lighting, and construction—seek not just reliable suppliers, but partners in innovation, Silver City Aluminum stands ready to provide customized extrusion solutions that reflect a commitment to excellence and environmental stewardship.

Choosing Silver City Aluminum means engaging with a company that understands the intricate balance between performance, efficiency, and sustainability. With a commitment to leveraging recyclable aluminum, extensive service offerings, and a customer-centric approach, they deliver tailored solutions that not only meet but exceed client expectations. Innovation, integrity, and sustainability are thus woven into the fabric of what they offer.

Looking for expert guidance or custom aluminum solutions for your next project? Our team at Silver City Aluminum is ready to assist with your extrusion, fabrication, and finishing needs. Whether you’re working on a new design or need advice on complex requirements, feel free to call us at 508-824-8631 or email us at engineering@scaluminum.com. Let’s make your vision a reality with precision and quality!