The Emergence of Custom Extruded Aluminum in Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, companies strive to enhance efficiency and produce high-quality outputs. Among the innovators in this space is custom extruded aluminum, a remarkable material that exemplifies strength, versatility, and light weight. As manufacturers look to improve processes and meet the rising demands of various sectors, custom extruded aluminum has been pivotal in driving innovative solutions. This trend signifies a broader transformation in how products are developed and manufactured across multiple industries.

Custom extruded aluminum is not merely a material of convenience; it represents a strategic choice for manufacturers aiming for right-weight structural integrity. Its lightweight nature is particularly advantageous in industries like aerospace and automotive, where every ounce counts toward performance and efficiency. For example, a top automotive manufacturer recently reported a 15% reduction in vehicle weight after integrating custom aluminum extrusions into their designs. This shift not only improved fuel efficiency but also enhanced the durability of essential components, providing a clearer understanding of how aluminum choices impact overall product performance.

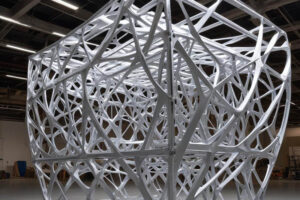

Furthermore, the versatility of custom extruded aluminum allows for shaping into an extensive range of profiles and sizes. This adaptability opens doors for applications that require unique designs, from elaborate lighting fixtures to sturdy marine hardware. By utilizing a single material across diverse product lines, manufacturers can streamline their operations and achieve a more cohesive production process. A compelling case study from the lighting industry indicates that custom aluminum tracks and heat sinks have revolutionized LED lighting production, combining aesthetic value with functional efficiency. As industries look for innovative materials that can handle both design and performance requirements, custom extruded aluminum stands out as a frontrunner.

Benefits of Custom Extruded Aluminum

At the heart of custom extruded aluminum’s appeal are its numerous manufacturing benefits, which go beyond lightweight properties and versatility. Cost-effectiveness is a crucial advantage that draws many manufacturers to this material. With the capacity for rapid production timelines and limited material waste, companies can reduce overall costs while maximizing output quality. A prime example of this is Silver City Aluminum, where innovative automated processes yield efficient production rates, significantly shortening lead times compared to industry standards without sacrificing product quality.

The rapid production timelines offered by custom extruded aluminum enhance a company’s ability to respond swiftly to market changes. Traditional manufacturing often involves lengthy lead times and potential delays. In contrast, as mentioned earlier, Silver City Aluminum’s standard lead times of just three to four weeks facilitate a more agile response mode in an ever-competitive environment. Companies can meet customer demands without the fear of long delays that may lead to lost business opportunities.

Moreover, the environmental aspect cannot be overlooked. The commitment to using 99.9% recyclable aluminum reflects a growing trend toward sustainability in manufacturing. As industries increasingly prioritize eco-friendly practices, the ability to integrate custom extruded aluminum into production can also improve a company’s green credentials. Businesses that adopt aluminum with minimal environmental impact witness not only operational cost benefits but also an enhanced brand image in the eyes of environmentally-conscious consumers.

The Precision Engineering Capacity of Custom Aluminum Extrusions

Precision engineering is a hallmark of custom aluminum extrusions, amplifying their appeal in manufacturing. When precision is paramount, the advanced technology employed in the extrusion process comes to the forefront. Silver City Aluminum utilizes state-of-the-art machinery that supports fully automated systems, allowing for real-time monitoring and adjustments throughout the extrusion process. This rigorous quality control ensures that every product produced meets the exact specifications laid out by the client.

Additionally, the intricacies involved in engineering custom solutions necessitate a partnership between manufacturers and extrusion providers. The collaborative approach is instrumental in developing specialized components for high-tech machinery or fabricated parts with intricate designs. By tapping into the expertise of providers like Silver City Aluminum, businesses can create seamless and efficient designs that meet their operational needs—all while maintaining a high standard of manufacturing benefits and performance.

Furthermore, the ability to manufacture custom aluminum extrusions up to 30 feet in length opens exciting avenues for large-scale projects. Industries requiring extensive profiles, such as construction and transportation, greatly benefit from this capacity. They can integrate custom extruded aluminum into massive frameworks or components, knowing that precision engineering has been a guiding principle throughout the design and production process.

Custom Aluminum Extrusions Across Various Industries

The practical applications of custom aluminum extrusions reflect their advantages in diverse sectors. For instance, in the marine industry, Silver City Aluminum’s collaboration with boat manufacturers resulted in custom extrusions engineered to resist corrosion—critical for prolonging the life of marine products subjected to harsh environmental conditions. By leveraging aluminum’s inherent qualities, manufacturers can enhance the safety and performance of their products, leading to higher customer satisfaction and loyalty.

In the realm of construction, the ability to produce custom frames and reinforcement profiles for doors and windows has proven invaluable. Silver City Aluminum’s specialization extends to thermal break systems that significantly improve insulation and energy efficiency in buildings. Not only does this lead to better environmental performance, but it also provides builders with robust, reliable products that can meet modern architectural demands.

Moreover, in the lighting sector, the production of custom aluminum tracks and heat sink profiles for LED systems demonstrates the ease with which designers can innovate. With the capability of tailoring extrusions to meet unique specifications, lighting manufacturers are free to explore creative avenues, implementing innovative fixtures that distinguish them in a competitive market. This flexibility is a vital component of success across industries, enabling manufacturers to keep pace with evolving consumer expectations.

The Customization Potential of Extruded Aluminum

One of the standout features of custom extruded aluminum is its profound potential for customization. This adaptability empowers manufacturers across different sectors to create tailored solutions that address specific challenges. The partnership between clients and providers like Silver City Aluminum fosters innovation, allowing companies to envision and realize complex designs that meet their unique requirements. The flexibility inherent in aluminum extrusion means that virtually any design can be developed—be it for construction applications, high-tech devices, or specialized systems.

This customization capability not only addresses current market needs but also anticipates future requirements. As technology evolves, the demand for specialized components will only intensify. Manufacturers that proactively engage with custom extrusion providers will find the support they need to stay ahead of the curve. Whether designing unique door and window framing systems for new builds or producing components tailored for cutting-edge machinery, the possibilities for innovation with custom extruded aluminum are virtually limitless.

In essence, the ability to work together to create custom solutions fosters a sense of partnership and collaboration that benefits both manufacturers and providers. By sharing expertise and insights, companies can innovate together, resulting in products that resonate with market demands. As industries become increasingly dynamic, this collaborative spirit will serve as a cornerstone for success in the development of custom extruded aluminum products.

Choosing Silver City Aluminum as Your Partner

As businesses navigate the challenges of competitive markets, the selection of a reliable extrusion partner becomes critical. Silver City Aluminum stands out with decades of experience in delivering precision-engineered aluminum solutions tailored to meet a myriad of industry needs. Their comprehensive understanding of custom manufacturing processes, coupled with their commitment to quality control and customer support, positions them as an ideal partner for organizations looking to innovate and grow.

Moreover, Silver City Aluminum’s quick lead times and responsiveness underscore their dedication to client satisfaction. While many extruders adhere to industry-standard timelines of one to one-and-a-half months, Silver City Aluminum maintains lead times of just three to four weeks, with special urgency options available within three days for critical projects. This kind of efficiency can be the difference between winning and losing contracts in today’s fast-paced market.

Finally, the company’s emphasis on environmentally sustainable practices reinforces their commitment to leaving a positive footprint on the world. The use of 99.9% recyclable aluminum not only showcases their innovative capabilities but also appeals to organizations seeking to enhance their green initiatives. By partnering with Silver City Aluminum, companies can prioritize both exceptional quality and environmental responsibility—an increasingly important consideration for today’s conscientious consumers.

Conclusion

In conclusion, the advantages of custom extruded aluminum have ignited a transformative wave across modern manufacturing. The material’s lightweight strength, versatility, and cost-effectiveness represent compelling reasons for its adoption in production strategies. Additionally, companies that collaborate with experienced partners like Silver City Aluminum benefit from enhanced efficiency and product quality, adding a significant competitive edge in today’s dynamic market landscape.

As industries continue to evolve and consumer demands shift, custom extruded aluminum will play a pivotal role in the ongoing quest for innovative, sustainable solutions. Those who embrace this advanced material will find themselves well-positioned to adapt and succeed in an ever-changing environment. With its myriad manufacturing benefits becoming increasingly evident, custom extruded aluminum is not just a material choice; it is a strategic decision for forward-thinking manufacturers.

For those looking to harness the benefits of custom extruded aluminum, Silver City Aluminum is ready to assist with high-quality custom aluminum extrusions, fabrication, and finishing services tailored to meet your project needs. Reach out today to discover how Silver City Aluminum can elevate your manufacturing processes and help you meet your goals with precision and efficiency.

Contact Information:

Address: 704 West Water Street, Taunton, MA 02780

Phone: (508) 824-8631

Email: engineering@scaluminum.com or sxavier@scaluminum.com

Website: scaluminum.com

Looking for expert guidance or custom aluminum solutions for your next project? Our team at Silver City Aluminum is ready to assist with your extrusion, fabrication, and finishing needs. Whether you’re working on a new design or need advice on complex requirements, feel free to call us at 508-824-8631 or email us at engineering@scaluminum.com. Let’s make your vision a reality with precision and quality!