Introduction

Imagine having the power to transform your manufacturing processes and cut costs with a single decision—designing custom aluminum extrusion profiles. At Silver City Aluminum, we understand the critical role that personalized solutions play in enhancing efficiency and driving down expenses for businesses across various industries. In this article, we’ll dive into the significance of tailored profiles, spotlight successful projects, and offer practical tips for collaborating with experts in this field to achieve your objectives.

Custom aluminum extrusion design is at the forefront of innovative manufacturing solutions. Companies that incorporate these profiles into their production methodologies discover a plethora of benefits, from enhanced performance to significant cost-saving solutions. The strategic development of custom profiles not only meets specific technical requirements but also optimizes resources. Thus, the ripple effect of choosing the right extrusion design extends far beyond aesthetics; it influences operational efficiency, resource utilization, and overall manufacturing success.

By focusing on collaboration and precision, Silver City Aluminum has honed its approach to ensure that each client receives a product that not only aligns with their vision but also contributes to improved efficiency in manufacturing. As we explore the impact of custom designs, you will gain insights into how your unique needs can be met through innovative extrusion solutions. Ready to find out how tailored profiles can revolutionize your manufacturing process? Let’s dive into this exciting world!

The Impact of Custom Design on Manufacturing

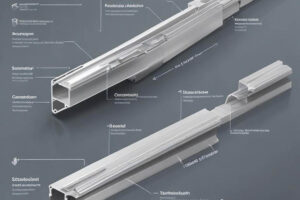

Custom aluminum extrusion profiles are not just about aesthetics; they can significantly streamline manufacturing processes. When a product is designed with functionality and manufacturing efficiency in mind, it minimizes waste and reduces the need for extensive secondary operations. Silver City Aluminum leverages advanced technology and precise engineering to create profiles that meet exact specifications, ultimately resulting in faster production and fewer resources consumed.

The process begins with a comprehensive understanding of the project requirements. Our engineering team collaborates closely with clients to identify specific goals, allowing us to craft tailored profiles that enhance performance while also being mindful of material costs. By analyzing the requirements, we avoid unnecessary complexities and focus on developing solutions that resonate with the client’s operational realities. This leads to smoother production cycles, less downtime, and an overall reduction in manufacturing resources.

Moreover, using custom aluminum extrusion profiles enables increased flexibility in design applications, making them suitable for various industries such as automotive, marine, and construction. Such versatility empowers manufacturers to create specialized products that can adapt to unique environmental challenges or regulatory standards. Ultimately, the impact of custom design goes beyond simple construction; it paves the way for innovative applications that redefine traditional manufacturing paradigms.

Case Studies of Success

Let’s take a look at a few standout projects that highlight the advantages of using custom extrusion profiles to save time and materials. For instance, a major lighting manufacturer approached Silver City Aluminum for a unique track system that needed to accommodate diverse lighting configurations. By optimizing the profile’s design, we were able to decrease the extrusion length without sacrificing performance, leading to a remarkable reduction in aluminum waste and a quicker lead time. Clients benefitted not only from reduced material costs but also from increased market responsiveness.

Similarly, a marine client needed custom railings designed to withstand harsh sea conditions. By engineering profiles that integrated strength and durability, we not only expedited production but also enhanced the product’s lifecycle and reduced repair costs. The final product provided a perfect blend of safety and style, illustrating how tailored designs can contribute to high-quality finishes while accommodating demanding industry standards.

These case studies serve as prime examples of how custom extrusion design can lead to significant triumphs in both efficiency and cost-saving solutions. From initial discussions about specific needs to the final production stages, the collaboration between Silver City Aluminum and our clients has repeatedly demonstrated a commitment to precision engineering that delivers exceptional results.

Enhancing Cost Efficiency

Cost savings in manufacturing aren’t just about using fewer materials; they also stem from the efficiency of the entire process. Custom extrusion profiles can simplify assembly, reducing labor hours and speeding up time to market. For example, the custom frames for doors and windows produced by Silver City Aluminum are designed to be easily integrated into existing systems, saving our clients substantial amounts in labor and potential rework due to compatibility issues.

By optimizing designs for ease of assembly, we ensure that the overall production timeline is shortened, enabling faster time-to-market for our clients’ products. Traditional manufacturing processes often involve multiple assemblies or complex joining techniques, which increase labor costs and extend production cycles. However, through custom extrusion design, we streamline these processes, resulting in better allocation of labor and ultimately, significant savings.

The consequences of enhanced cost efficiency radiate through every layer of the business. As companies optimize their resources through custom profiles, they can redirect those savings into other areas of growth, such as innovation, customer service, or expanding their product range. For manufacturers keen to maintain competitiveness in a rapidly changing market landscape, these cost-saving solutions have become invaluable.

Tips for Collaborating with Experts

To make the most of custom aluminum extrusion profiles, it’s essential for businesses to work closely with experienced manufacturers like Silver City Aluminum. Begin by clearly defining your project’s requirements and expectations. Engaging in open dialogue about your goals will enable us to identify solutions that align perfectly with your needs. A successful collaboration hinges on thorough understanding; sharing insights about your intended application, budget constraints, and desired timelines will lay the groundwork for effective project management.

It’s also vital to provide accurate sketches and specifications, allowing for precise engineering from the outset. Precise documentation reduces the likelihood of miscommunication and helps ensure that the designs translate seamlessly from paper to production. The more clarity we have from the beginning, the more effectively we can engineer custom profiles that reflect your vision and yield the best results.

Finally, don’t hesitate to discuss any potential design modifications; our team is always eager to offer input to enhance your project’s manufacturability. Frequent interactions throughout the design process foster a culture of innovation and responsiveness, as both parties are engaged in refining the solution. By leveraging our expertise in custom extrusion design, businesses can enhance both the quality of their final products and their operational outcomes.

The Role of Prototyping and Feedback

Never underestimate the power of prototyping and feedback in the world of custom extrusion design. At Silver City Aluminum, we often recommend clients start with prototypes to test and refine their designs before full production. This iterative approach helps identify potential issues early, ensuring a smooth transition to the final product. With prototypes, businesses can visualize how their custom profiles will perform in real-world applications, enabling informed decision-making.

Moreover, maintaining an ongoing feedback loop during the prototyping phase can lead to additional optimizations and cost-saving solutions, as adjustments can be made in real-time. By sharing performance metrics and user experiences, you benefit from the collective knowledge amassed over years of industry experience. This collaboration ensures that each client’s priorities are prioritized, leading to an end product that meets all operational benchmarks.

Incorporating customer feedback also reinforces the commitment to continuous improvement. As we gather data on the prototypes’ performance, we can utilize that information to refine our processes, enhance design iterations, and ultimately deliver superior products. The prototyping stage represents a crucial intersection where innovation, functionality, and client specifications converge, fostering an environment ripe for groundbreaking advancements in custom aluminum extrusion solutions.

Conclusion

Designing custom aluminum extrusion profiles is an incredible opportunity for businesses to streamline manufacturing processes and reduce costs dramatically. With examples from our successful projects proving the benefits, coupled with our dedication to collaboration and innovation, Silver City Aluminum stands ready to partner with you in achieving your manufacturing objectives. Let’s work together to create tailored solutions that not only meet your specifications but also propel your business towards greater efficiency and cost-saving solutions. Reach out today, and let’s turn your custom design ideas into reality!

Looking for expert guidance or custom aluminum solutions for your next project? Our team at Silver City Aluminum is ready to assist with your extrusion, fabrication, and finishing needs. Whether you’re working on a new design or need advice on complex requirements, feel free to call us at 508-824-8631 or email us at engineering@scaluminum.com. Let’s make your vision a reality with precision and quality!