Introduction to Custom Aluminum Extrusion

In today’s competitive landscape, industries are constantly on the lookout for innovative materials and manufacturing processes that can enhance their products’ overall quality and efficiency. Custom aluminum extrusion is emerging as a versatile solution, offering many benefits for businesses across various sectors, from marine to automotive and construction. Companies like Silver City Aluminum exemplify how customized aluminum solutions can significantly impact design flexibility, waste reduction, and sustainability.

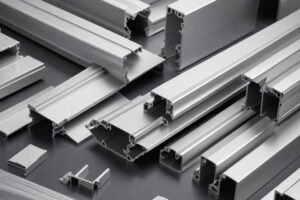

Custom aluminum extrusion involves shaping aluminum into specific profiles by pushing it through a die. Extrusion can produce complex designs that are often impossible with traditional manufacturing techniques. According to a report from the Aluminum Association, this process has become increasingly prominent due to the lightweight and corrosion-resistant properties of aluminum, making it an ideal material for various applications.

The application of custom aluminum extrusion is vast, thanks to aluminum’s lightweight nature, high strength-to-weight ratio, and excellent thermal and electrical conductivity. Industries are continually discovering new ways to incorporate aluminum extrusions into their products, enhancing performance while simultaneously cutting costs. The benefits of aluminum make it a go-to choice for innovative businesses looking to stay ahead of the curve.

The Advantages of Design Flexibility

One of the primary benefits of aluminum extrusion lies in its design flexibility. Unlike traditional manufacturing methods, extrusion allows for the creation of intricate shapes and profiles tailored to the specific needs of different applications. With advanced technology and machinery, precision-engineered aluminum profiles can be developed to meet even the most complex design requirements. This capability empowers designers and engineers to push creative boundaries, ultimately improving product aesthetics and functionality.

For example, a project in marine manufacturing required a custom aluminum extrusion that could withstand harsh marine environments while maintaining aesthetic appeal. By leveraging the design flexibility of aluminum extrusion, engineers created a solution that seamlessly integrated with existing designs while providing enhanced durability. Such outcomes demonstrate how custom aluminum extrusion can support innovative engineering concepts, allowing for diverse applications across various sectors.

In addition to enhancing aesthetic flexibility, the ability to incorporate complicated geometries allows manufacturers to improve overall product functionality. Consider the recent advancements in lighting applications; companies can design LED heat sinks tailored to maximize thermal management, contributing to improved longevity and efficiency. As customized profiles become more common, businesses can expect to differentiate their products in competitive markets effectively.

Waste Reduction Through Efficient Processes

Alongside design flexibility comes the capability for waste reduction. The extrusion process utilizes aluminum billets made from 99.9% recyclable materials, ensuring an efficient use of resources. By producing components to specified dimensions and avoiding unnecessary cutting and machining, companies can significantly minimize waste generated during production. This not only reduces costs but also enhances the overall sustainability of the manufacturing process—a win-win for both businesses and the environment.

The efficiency of aluminum extrusion is evident in its production yield. The ability to create parts with less material wastage compared to traditional machining methods means that companies can realize significant cost savings. For instance, a project involving a series of custom brackets saw substantial reductions in material waste and operating costs thanks to the precision engineering capabilities offered by custom aluminum extrusion. Such outcomes lend themselves to improved profitability and resource management.

Moreover, the eco-conscious approach demonstrated by the aluminum extrusion process leads to positive long-term relationships with clients concerned about their environmental impact. Being able to proactively address waste management not only benefits the bottom line but also aligns with the growing expectation for sustainable manufacturing practices. Companies can take pride in inking contracts with suppliers that champion both quality and environmental responsibility.

The Role of Sustainability in Manufacturing

Sustainability is a crucial aspect of modern manufacturing, and custom aluminum extrusion plays a pivotal role in this arena. Silver City Aluminum is committed to environmentally friendly practices, prioritizing recyclable materials and implementing eco-conscious manufacturing processes. By sourcing aluminum that is nearly entirely recyclable and allowing for seamless reusability in future projects, companies can reduce their carbon footprint and contribute to a more sustainable future.

Aluminum itself is known for its recyclability, with over 75% of aluminum ever produced still in use today. The intrinsic characteristics of aluminum allow it to be easily melted down without degrading its quality, making it an ideal material for companies looking to incorporate sustainable practices into their production processes. This commitment to recyclable materials has positioned businesses like Silver City Aluminum at the forefront of sustainability in the industrial sector.

Furthermore, innovative extrusion techniques not only maximize the use of available aluminum but also emphasize energy-efficient production methods. Companies focused on sustainable manufacturing will find that custom aluminum extrusion allows for cleaner processes, contributing to lower overall emissions during production. As clients increasingly demand sustainable solutions, adopting custom aluminum extrusion processes will only boost a business’s attractiveness and marketability.

Real-World Applications and Case Studies

To further illustrate the effectiveness of custom aluminum extrusion, many businesses have shared their positive experiences. A lighting manufacturer collaborated with Silver City Aluminum to develop a custom LED heat sink, resulting in improved performance and longevity of their product. The flexibility offered by aluminum extrusion allowed for innovative designs that enhanced heat dissipation while fitting seamlessly within the manufacturer’s existing product line.

This real-world application underscores the intrinsic advantages of custom aluminum extrusion. By utilizing the design flexibility inherent in this process, the lighting manufacturer could create a superior product that not only met but exceeded customer expectations with enhanced performance criteria. Furthermore, this collaboration represents a strategic partnership between manufacturer and supplier that fosters innovation and product improvement.

Further testimonials from clients across various industries echo the reliability and quality of Silver City Aluminum’s services. They consistently commend the company’s commitment to quick lead times and meticulous attention to detail. Clients value the seamless collaboration throughout the project, which ultimately leads to successful outcomes that meet stringent deadlines and performance requirements. This trust fosters stronger business relationships and enhances the overall industry reputation for custom aluminum suppliers.

Diverse Applications Across Industries

The versatility of custom aluminum extrusion extends beyond single sectors. In the marine industry, for example, Silver City Aluminum has crafted custom extrusions for boat rails and decking materials designed to endure harsh environmental conditions while maintaining durability and aesthetic appeal. This adaptability highlights aluminum’s integral role in a variety of applications—from construction and automotive parts to specialized lighting fixtures—creating countless opportunities for innovation.

In construction, the reliability of aluminum’s strength and light weight make it a preferred choice for structural components and architectural features. Silver City Aluminum’s experience includes creating strong window and door frames that meet stringent building codes while providing an appealing aesthetic. Similarly, automotive manufacturers have embraced custom aluminum extrusions to enhance vehicle performance by reducing weight while maintaining structural integrity—an alignment with today’s movement towards energy-efficient vehicles.

The advancement of technology has further propelled the versatility of custom aluminum extrusion. Companies can use software to model and analyze designs virtually, leading to better decision-making during the design phase. This not only saves time but also ensures that the most suitable extrusion profiles are applied in real-world applications across industries, enhancing usability and performance as market needs evolve.

Why Choose Silver City Aluminum?

Silver City Aluminum has positioned itself as a leader in providing custom aluminum extrusion, fabrication, and finishing services focused on meeting the unique demands of various industries. The company’s decades of experience translate directly into delivering precision-engineered aluminum extrusions tailored to fit exact specifications, making them a trusted partner in innovation.

The speed is also a hallmark of Silver City Aluminum’s service, with standard lead times of 3 to 4 weeks compared to the industry norm of 1 to 1.5 months. This quick turnaround is complemented by the ability to accommodate urgent requests, showcasing Silver City Aluminum’s commitment to client satisfaction and consistency of service—critical aspects that build long-lasting partnerships.

Moreover, the company’s focus on sustainable manufacturing practices is an integral component of its operations. Their specialized processes emphasize maximizing the recyclability of materials while minimizing waste. In an era where businesses must be increasingly vigilant about environmental issues, Silver City Aluminum leads the way in sustainable manufacturing, allowing clients to meet their eco-friendly goals while still achieving high-quality results.

Conclusion: Embracing Innovation with Custom Aluminum Extrusion

In conclusion, the multifaceted advantages of custom aluminum extrusion make it a critical component for businesses seeking to enhance their products. With increased design flexibility, reduced waste, and a focus on sustainable manufacturing, companies can leverage the benefits of tailored aluminum solutions to improve their offerings and contribute to a more eco-friendly manufacturing landscape. As illustrated through real-world applications and client testimonials, investing in custom aluminum extrusion is a step toward embracing innovation and achieving excellence in product design and fabrication. Silver City Aluminum stands ready to partner with businesses, providing top-tier services to meet their unique project needs.

If you’re looking for high-quality custom aluminum extrusions, fabrication, and finishing services, Silver City Aluminum is here to assist with all your project needs. Explore our solutions today!

Looking for expert guidance or custom aluminum solutions for your next project? Our team at Silver City Aluminum is ready to assist with your extrusion, fabrication, and finishing needs. Whether you’re working on a new design or need advice on complex requirements, feel free to call us at 508-824-8631 or email us at engineering@scaluminum.com. Let’s make your vision a reality with precision and quality!