Introduction

In today’s fast-paced manufacturing landscape, businesses are constantly seeking ways to streamline processes, reduce costs, and optimize efficiency. One effective approach to achieving these goals is through the use of standard aluminum extrusions. Companies like Silver City Aluminum have perfected this art, providing ready-made profiles that not only save time and money but can also be tailored to meet specific project requirements. The introduction of standard aluminum extrusions has revolutionized the industry, promoting efficient production and meeting diverse client needs without the excessive overhead often associated with custom jobs.

The world of manufacturing has never been more competitive, with companies striving to outpace one another in terms of delivery speed, cost reduction, and quality. By implementing standard aluminum extrusions into their manufacturing processes, businesses can respond to market demands more nimbly. This approach not only streamlines operational tasks but also allows companies to allocate their resources more judiciously. Firms can quickly initiate designs from existing profiles, facilitating faster project turnaround and enhancing customer satisfaction.

Silver City Aluminum stands at the forefront of this transformation, demonstrating how standard aluminum extrusions can yield cost-effective aluminum solutions tailored for a wide range of applications. By promoting productivity and efficiency, companies like Silver City Aluminum have positioned themselves as essential players in various industries, providing manufacturers with the tools they need to thrive in an ever-evolving landscape.

Understanding Standard Aluminum Extrusions

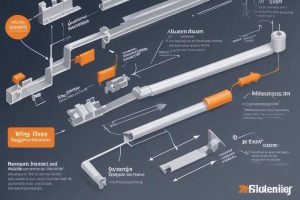

Standard aluminum extrusions are pre-designed profiles that cater to a variety of applications, from construction to automotive. The extrusion process involves forcing heated aluminum billets through steel dies to produce specific shapes or profiles. This method ensures uniformity and precision in the resulting extrusions, making them ideal for various manufacturing projects. It’s a critical process that translates into quality products, ready for implementation in numerous sectors.

Utilizing standard profiles allows manufacturers to significantly cut down on design time, reduce material waste, and improve overall production speed. When designs are already established, businesses can skip the early phases of the engineering cycle, leading to time-saving manufacturing and quicker displacement of products to market. Employing standard aluminum extrusions represents a streamlined approach that not only boosts productivity but also capitalizes on market-driven efficiencies and resource optimization.

The versatility of standard aluminum extrusions is reflected in their wide-ranging applications across different industries. From building frames that necessitate strength and integrity to lightweight parts in automotive engineering, these profiles can be tailored for performance without straying from established specifications. This is crucial for companies that require dependable solutions that also fit into tight production schedules and budgets.

The Cost-Effectiveness of Standard Profiles

Opting for standard aluminum extrusions can lead to considerable cost savings, a factor that resonates strongly with businesses conscious of their bottom line. Without the need for extensive engineering and production processes, organizations can avoid hefty setup costs that are typically associated with custom designs. This aspect of using standard profiles is particularly attractive for startups and small manufacturers that may lack the capital to invest heavily in custom fabrication.

Moreover, the shorter lead times associated with standard profiles allow manufacturers to push products to market faster, further enhancing their competitive edge. The reduced complexity in manufacturing processes results in fewer hours logged and lowers labor costs, translating into a more favorable financial forecast. When a business can maintain optimal output levels while spending less on raw materials and production, it creates a sustainable model worth emulating.

In terms of creating cost-effective aluminum solutions, the implementation of standard extrusions provides a clear path. Companies that engage Silver City Aluminum benefit from reduced operational costs while enjoying high-quality products that do not compromise on performance or aesthetic appeal. This fiscal prudence, combined with the advantages of quality materials, leads to an overall better return on investment for clients choosing to work with established extrusion providers.

Tailoring Standard Profiles to Specific Needs

While standard profiles are ready-made, Silver City Aluminum offers the flexibility to customize these extrusions, ensuring they meet unique project specifications. This feature allows clients to benefit from the time savings of standardization while still having the opportunity to tailor dimensions, finishes, and other features according to specific needs. It’s a win-win situation that combines efficiency with customization, addressing the diverse needs of industries ranging from automotive to marine applications.

Customization does not conflict with the speed and efficiency that standard extrusions promise. Instead, it enhances the appeal of these profiles by providing a layer of personalization that serves clients better. For instance, a construction firm can obtain standard extrusions for window frames and adapt them to meet architectural requirements without embarking on a lengthy design process. This saves time and enables expedited projects, which is particularly essential for expedited projects.

The relationship between standardization and customization in aluminum extrusions promotes flexibility, allowing businesses to develop innovative designs while capitalizing on the advantages offered by existing profiles. Silver City Aluminum’s ability to deliver tailored solutions ensures that every client can achieve a product that not only meets their operational needs but also aligns with their branding and functional requirements.

Ordering and Logistics Made Simple

Silver City Aluminum has developed a streamlined ordering process that maximizes efficiency for clients. The focus on simplicity and clarity helps businesses place orders quickly, allowing them to concentrate on their operations without the hassle of lengthy procurement procedures. Clear communication, alongside a commitment to rapid processing, ensures that clients can navigate the ordering process with ease.

Furthermore, the company’s comprehensive logistics services ensure that products are delivered on time, allowing clients to plan their projects confidently. Communication throughout the logistics chain serves as an integral part of client satisfaction. Clients benefit from timely updates and notifications regarding order status, significantly reducing uncertainty that often accompanies manufacturing logistics. Whether a project requires standard aluminum extrusions or customized solutions, Silver City Aluminum’s logistics network accommodates various delivery needs, ensuring goods arrive when they are most needed.

This dedicated approach to ordering and logistics keeps operations running smoothly, enabling businesses to allocate their resources efficiently while focusing on core functions. A simplified procurement process, paired with dependable logistics, can elevate the entire production cycle, enhancing customer confidence and overall satisfaction with the end result.

Quality Assurance and Consistency

The use of standard aluminum extrusions from a reputable supplier like Silver City Aluminum guarantees quality and consistency across all products. Their advanced manufacturing techniques ensure that every extrusion meets stringent quality control standards, minimizing the risk of defects and the need for costly reworks. In an industry where precision is non-negotiable, companies that prioritize quality typically enjoy stronger market positions.

This emphasis on quality assurance reflects Silver City Aluminum’s commitment to best practices and continuous improvement. The company’s comprehensive quality protocols, which include real-time monitoring and regular inspections, foster an environment where excellence is expected and achieved. Clients can trust that the extrusions they receive will perform as required, ultimately boosting their overall reputation in their respective markets.

Quality isn’t just about the final product; it encompasses every step of the manufacturing process. By integrating quality control throughout their production cycle, Silver City Aluminum ensures that consistency is a hallmark of their services. This leads to fewer production setbacks, allowing clients to depend on their products and remain competitive while delivering their own offerings to market.

Customer Satisfaction and Support

Silver City Aluminum prides itself on exceptional customer service, which sets the company apart from the competition. Clients can expect personalized support throughout the entire process, from initial inquiries to delivery. Establishing strong relationships with clients is vital to the company’s ethos and contributes to its success over the years.

This dedication to customer satisfaction ensures that every need is met, reinforcing the partnership aspect of the relationship. Clients are encouraged to communicate their requirements comprehensively, allowing the team at Silver City Aluminum to provide tailored solutions that reflect the unique demands of each project. Establishing a supportive dialogue fosters an environment where feedback is welcomed, creating opportunities for further enhancements and improvements.

Silver City Aluminum’s commitment to service excellence ensures that clients feel valued and supported every step of the way. This exemplary support structure adds significant value to the overall experience, reinforcing client loyalty and trust in Silver City Aluminum as their choice for aluminum solutions.

Conclusion

In conclusion, standard aluminum extrusions offer a practical solution for businesses looking to save time and money while still achieving high-quality results. With expert providers like Silver City Aluminum, manufacturers can enjoy the benefits of ready-made profiles alongside the ability to customize to their specifications. The efficient processes that have been established not only alleviate the challenges associated with custom jobs but also promote a culture of responsiveness to market demands.

Streamlining the ordering process, ensuring consistent quality, and providing dedicated support positions Silver City Aluminum as a reliable partner in the world of aluminum solutions. As businesses continue to navigate competitive landscapes, adopting innovative methods like standard aluminum extrusions will be paramount for those aiming to maintain an edge. The emphasis on quality, customization, and efficient logistics makes Silver City Aluminum an ideal ally for those in need of aluminum fabrication and finishing services.

For high-quality custom aluminum extrusions, fabrication, and finishing services, Silver City Aluminum is ready to assist with all your project needs. Reach out today to discover how they can support your next project!

Looking for expert guidance or custom aluminum solutions for your next project? Our team at Silver City Aluminum is ready to assist with your extrusion, fabrication, and finishing needs. Whether you’re working on a new design or need advice on complex requirements, feel free to call us at 508-824-8631 or email us at engineering@scaluminum.com. Let’s make your vision a reality with precision and quality!